Part V. Planchet Errors:

Blanking and Cutting Errors:

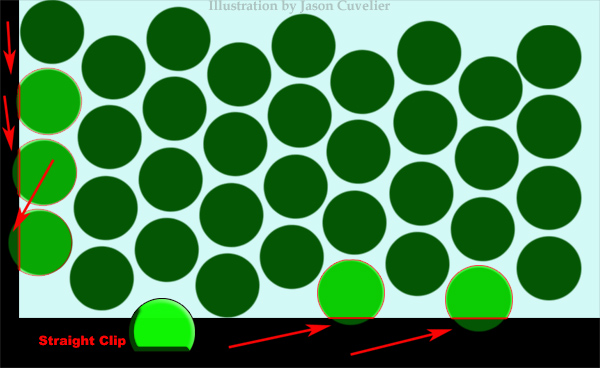

Straight clips

Definition: A straight clip is thought to result when a blanking die (punch) slices through the leading or trailing end of the coin metal strip. This pre-supposes that the ends were trimmed prior to the coil being fed into the blanking press.

Another possibility is the blanking die slicing through one side of a strip that is too narrow. This situation might arise if the splitter, which divides the original wide strip into narrower slips, is not positioned right in the middle of the coil.

A small percentage of straight clips mark the termination of a planchet taper. This may be where the rollers squeezed the leading or trailing end of the strip down to an abnormally thin gauge.

The edge texture of a straight clip is highly variable. It can be smooth, rough, irregular, or serrated in some fashion. This probably reflects a variety of machines employed for the task — shears, saws, guillotines are three possibilities.

A straight clip appears on a coin as a straight edge. Not all straight edges are straight clips, however. They are sometimes confused with chain strikes, broken planchet and broken coin errors, and various forms of pre-strike damage. When a straight-clipped planchet is struck out of collar, the straight edge often bows out due to the pressure of the strike and attendant expansion of the coin. These secondarily convex straight clips have been mistaken for elliptical clips.

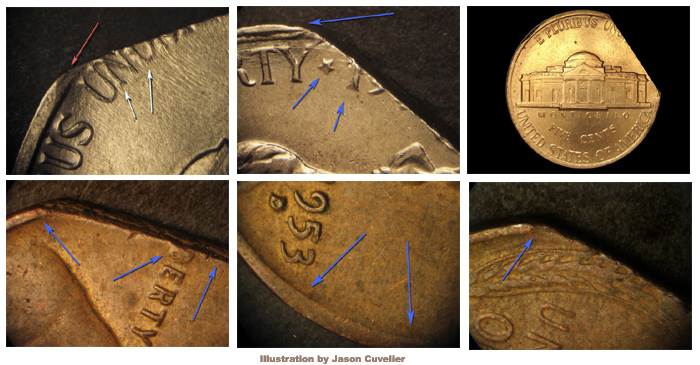

For expanded treatment concerning clip diagnostics click here.

|