PART II. Die Varieties:

Doubled Dies

Definition: A doubled die (hub doubling) is caused by a misalignment or a mismatch between a working hub and a working die. The misalignment or mismatch occurs between a first and subsequent hubbing or sometimes in the course of a single hubbing. Misalignments can occur along three orthogonal planes and three orthogonal axes. Doubled dies that are the result of a misalignment are variously characterized as rotated, offset, pivoted, or tilted. Doubled dies that are the result of a design mismatch are variously characterized as “distended”, “distorted”, “modified” and “design hub doubling”. A total of eight classes are recognized.

Coins struck from a doubled die will show doubling of the design elements. Doubling can be limited to one element or encompass much of the design. Doubling can be subtle or so extreme as to produce entirely separate elements of equal strength. All coins struck from a doubled die will show the same degree of doubling from coin to coin.

The correct terminology for this anomaly is “doubled die” or “hub doubling”. No other term is acceptable.

CLASS I- Rotated Hub Doubling:

“Rotated hub doubling occurs when the die is turned either clockwise or counter clockwise on an axis near the center of the design between hubbings. It is characterized by having all devices nearer the rim doubled the most,while those near the center of the design are not doubled at all” ¹

1955-P Lincoln cent with rotated hub doubling or Class I.

Photographs courtesy of Coppercoins

1972-P Lincoln cent with rotated hub doubling or Class I.

Photograph courtesy of Coppercoins.

CLASS II – Distorted Hub Doubling:

“This class occurs when a hub flattens out between hubbings on a single die. This happens because the hubs are used to create a number of dies (often over a hundred). As with any malleable material, the steel flattens outward as it is used. If a die is first hubbed with a hub that is rather new and subsequently with an old hub, the devices near the outer edge will show doubling either towards the center of the design (flattened hub used first) or towards the edge of the design (flattened hub used last”.

“Class II hub doubling is most often characterized by doubling that parallels the outside edges of the devices closest to the rim. The two primary requirements are that the spread be directly toward or away from the rim (without rotation or pivot) and that there be clear separation lines in the doubling” ¹

1964P Lincoln cent with distorted hub doubling or Class II.

Photographs courtesy of Coppercoins.

CLASS III – Design Hub Doubling:

This class of hub doubling “is caused when two different hubs with different designs are used to create one die. The design differences can be as minor as the exact placement of a single letter or design feature, or it can be as major

as two differently dated hubs.”¹

“ALL examples of what people refer to as “over-dates” in the twentieth century coin types are actually Class III doubled dies. This includes the 1918/7 – D nickel, both 1942/1 dimes, the 1943/2-P nickel, as well as others.”¹

“Design hub doubling is characterized by a difference in some part of the design rather than a misalignment of the design.”¹

A 1960 Lincoln cent proof die and 1960-D business strike working die, along with a 1970-S Lincoln cent proof working die, were hubbed with both the small date and large date hubs.

Class III: 1918/7-D Nickel Class III: 1942/1-P Dime

Class III: 1960-D cent, small date over large date Class III: 1970-S cent, hubbed with large and small date

Photographs courtesy of Coppercoins

Class III: 1960-P Proof Lincoln cent hubbed with a small date over a large date.

Photographs courtesy of Coppercoins

CLASS IV – Offset Hub Doubling:

“Offset hub doubling is caused when a die is returned to the hubbing press but is shifted to one side. The result is doubling of the design in a single cardinal direction – north, south, east, southwest, etc. This form of doubling is found more often affecting the center of the design than other classes of doubling, because regardless of the strength of the offset, all devices, including those in the center of the design, will show the same spread of doubling”. ¹

Class IV doubled die found on the reverse of the 1983-P Lincoln cent. Notice that the doubling is shifted directly to the north.

Photographs courtesy of Coppercoins.

Class IV doubled die found on the obverse of a 1984-P Lincoln cent. Notice that the doubling is shifted directly to the south.

Photographs courtesy of Coppercoins

CLASS V– Pivoted Hub Doubling:

“This class of hub doubling is one of the more common types of doubling. Its cause is very similar to that of Class I rotated hub doubling in that the alignment of the die that created the doubling involves clockwise or counterclockwise rotation. But in the case of Class V hub doubling, the center of rotation is at or near the rim, causing more doubling on one side of the design (the area opposite the pivot point) and little or no doubling near the pivot point.” ¹

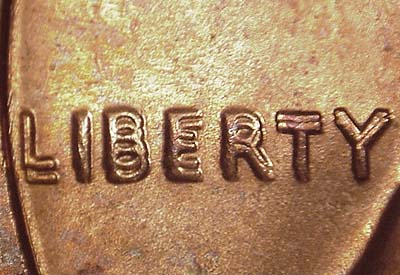

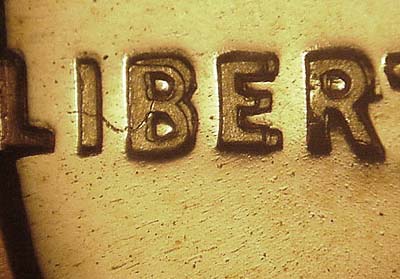

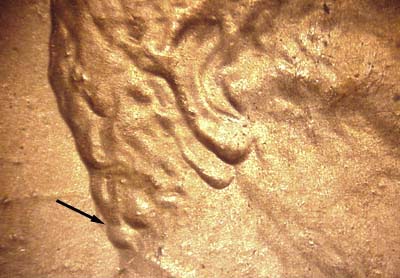

This is a Class V doubled die found on the obverse of a 1995-P Lincoln cent. Notice that there is a well defined doubling on the letters in LIBERTY. Even the letters in IN GOD show considerable doubling while the date shows virtually no doubling what so ever. The pivot point was near the date and accounts for this feature of no doubling on the date. The black arrows are indicators pointing to die markers found on the obverse die.

Photographs are courtesy of Coppercoins.

Photographs are courtesy of Coppercoins.

CLASS VI – Distended Hub Doubling:

“This class is generally caused by using hubs to impress designs into improperly annealed dies. The design flattens out and becomes stretched or die tended toward the outside of the design. Like CLASS II doubled dies, CLASS VI doubled dies generally show their characteristics close to the rim.

The picture below shows a strong class VI doubled die, found on the obverse die of a 1944-D Lincoln cent. Notice the extra thickness on the bottoms of the digits in the date.

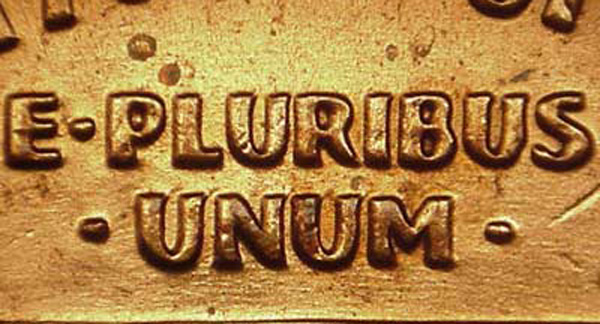

The pictures below show the same extra thickness in the motto E . PLURIBUS UNUM on the reverse die of a 1943 Lincoln cent. Notice the extra thickness in the dots and the bottoms of the letter U. This is a typical class VI doubled die. These photographs are courtesy of Coppercoins.

CLASS VII – Modified Hub Doubling:

“This class of doubling is caused when an errant part of the design is ground off a hub in an effort to replace it. If the errant portion of the design is not completely removed by the grinding it will leave its mark on any die created from the hub. The errant element is usually a digit or digits of the date, but it can be other parts of the design.” ¹

While modified hub doubling is an actual class, there is no substantiated evidence to prove that any examples of this class of doubling do exist. Any modification to a working hub that would show the type doubling described above would appear on numerous working dies and this has not been the case. It would also be senseless for the Mint to modify a working hub, use that hub to impress just one working die and then retire that hub; there has been no evidence to support that occurrence either. While there are various listings which have some Class VII doubled dies, there is no consensus between those various listing as to which particular dies are actually Class VII.

With the ambiguities surrounding this class of doubled dies, we shall not attempt to show examples of what this doubled die may appear as. However, we do support the definition of this class in hopes that a verifiable example

can be found.

CLASS VIII – Tilted Hub Doubling:

“Tilted hub doubling occurs when a die is set in the hubbing press tilted and rotated clockwise or counterclockwise from the hub. The resulting doubled die will show doubling on part of the design close to the rim, and the rest of the

design will be normal.” ¹

Again, some ambiguity surrounds this class of hub doubling. Some variety experts have included the tilted hub, instead of solely the tilted die, as the cause for this type of doubling. In this scenario the tilted hub accounts for

the majority of the single squeeze hubbed doubled dies (see Class IX) with or without a specific rotation to the hub.

A misnomer associated with this class is trail dies (including wavy steps). Some listings have this anomaly type under this class of die doubling. Our contention is that trail dies are not doubled dies and thus should not be listed under any class of hub doubling.

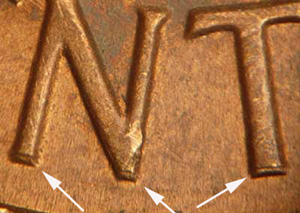

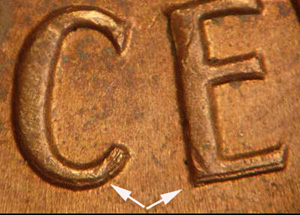

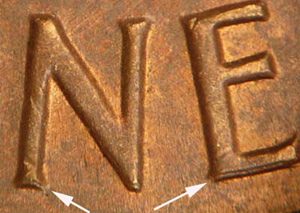

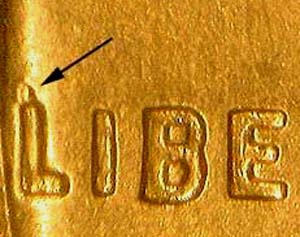

The photos below show a Class VIII hub doubling found on a 1964-P Lincoln cent. Notice the extra vertical bar above the L of LIBERTY and the slightly clockwise rotated second impression of the word IN.

All photographs are courtesy of Coppercoins

.

CLASS IX – SHIFTED HUB DOUBLING:

“This form of doubling happens when a slightly misaligned (tilted) die “pops” into position under the constant pressure of the hub and its thousands of pounds of force.” ¹

“It is most often characterized by a slippage of the design, in a cardinal direction – much like the Class IV offset hub doubling. It most often affects centrally located design elements. The main difference, with respect to causation, is that the design is never “picked up” off the die during the hubbing. Rather, it suddenly “slides” into place creating doubling in the design.” ¹

Once more there are some differences of opinions among the variety experts. John Wexler writes,” Class IX. God Only Knows – This class of doubling is for those doubled dies that are simply unexplained. It is for those extremely few doubled dies that defy logic and common sense. It is where the physical evidence does not support a reasonable conclusion on how the working die was hubbed to produce the secondary image.”

Those files that have the Class IX use it for listings of doubled dies that were made by the single squeeze hubbing system. However, this presents a problem for there is a grey area when the U.S. Mint used both the single squeeze and multiple hubbings to make dies. This transitional period extends from before 1986 (the first year that the U.S. Mint reported using the single squeeze hubbing system) to 1997 (when the single-squeeze hubbing was finally and fully implemented at both the Denver and Philadelphia mints for all denominations). This time span contains a lot of doubled dies that cannot be confidently assigned to one or the other hubbing system.

Again, there are some listings in the Class IX doubled dies that contain files for trail dies(wavy steps). We feel that this is incorrect and that trail dies, including what is called wavy steps, are not doubled dies, but a different type of anomaly.

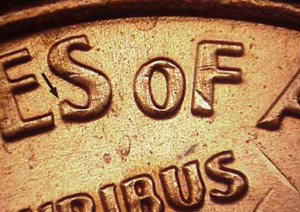

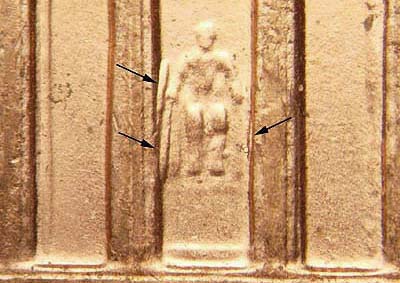

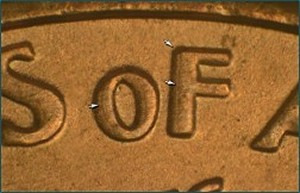

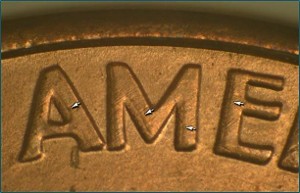

Notice the distortion seen in E . PLURIBUS . UNUM with extra thickness seen in the east / west plane. On early die state coins, division lines can be seen in the letters AME of AMERICA and the word OF. Also notice the split bottom serif on the last S of STATES.

These photographs are courtesy of Coppercoins

The second type of die doubling see with the single squeeze hubbing system occurs when the same offset in placement of the hub to the die occurs. Once again, the hubbing is initiated, but stopped by the press operator when the offset is detected. The the hub to die placement is correct and hubbing once again started. This start – stop – start of hubbing leaves Central located design doubling. Two examples of this type doubled die are shown below on 2004-P Lincoln cent reverse dies.

Photographs are courtesy of Coppercoins and taken by Gene Nichols.

Single squeeze hubbing produces doubled dies under two different scenarios. The first involves a hub that is offset relative to the die when the hubbing begins. During the hubbing, the offset is corrected by the increasing pressure that is felt on the hubbing plate, which causes the hub to slide into the correct position. Such doubled dies will have a “smeared” or elongated distortion to the design elements affected. Early die state coins will have division lines, along with split serifs, in the lettering and digits. Such an example is seen below which occurred on a 2004-P reverse die Lincoln cent.

Peripheral doubling is rare when the single squeeze hubbing system is used. The photos below show such doubling in the form of split serifs and division lines on the reverse of a 2004P Lincoln cent. The working hub had reached a point where most if not all of the design had already been transferred to the working die before the shift took place.

All photographs are from Billy Crawford.

Another example of single-squeeze peripheral design doubling occurs on a 2004-P Jefferson nickel, also known as the Peace nickel. Not only does the motto IN GOD WE TRUST show doubling, but also LIBERTY, the date, the star, the mint mark, the designer’s initials and Jefferson’s eyebrow.

¹ All quotations in this section are attributed to Chuck Daughtrey, unless otherwise indicated.