PART V. Planchet Errors:

Rolling / Bonding Mill Errors:

Missing Clad Layers:

Both Clad Layers Missing:

Core Thickness:

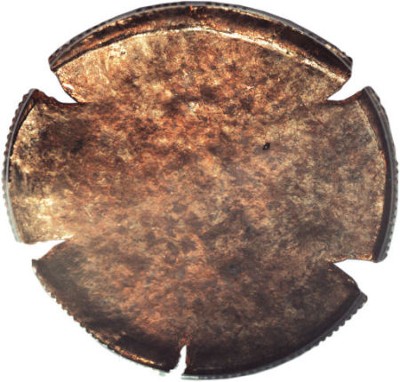

Definition: This type error occurs when both clad layers are improperly bonded and peel of the core of the planchet or coin. This error can also occur when the copper core is ganged punched from a strip where the copper core extends past the clad layers.

An undated copper core planchet was fed into the dies along with a normal quarter planchet. The strike adhered the copper core piece to the reverse die. The other coin was ejected, and a new planchet fed in. This cycle repeated until the multi-struck copper core piece stretched to the diameter of a half dollar, and developed edge splits. Copper core pieces are the result of improper bonding between the clad and copper layers, or can be created when the copper layer of the planchet strip extends beyond the two clad layers.

Image and text courtesy of Heritage Auctions.