Part V. Planchet Errors:

Bonding / Bonding Mill Errors:

Missing Clad Errors:

Before Strike:

Before Rolling is Completed:

Full

Definition: During the bonding process, two outer coils of thin clad strip (75% Cu / 25% Ni) are bonded to a middle coil of thick core strip composed of pure copper. If the leading end of one of the clad strips lags behind the other two strips during insertion into the bonding mill, the leading end of the composite strip will have only two layers instead of three. Likewise, if one clad strip terminates prematurely at the trailing end of the bonded strip, that trailing end will also only have two layers, one of copper-nickel and one of pure copper. In each case, the bi-laminar section of strip will be rolled to full thickness. Any blank punched out of that section of the strip will also weigh the same as a normal coin.

A normal-weight missing clad error will also result when a large gap is present or opens up within one of the clad strips. This gap will be filled by the copper core during bonding and subsequent rolling.

This is a very rare type of rolling mill error.

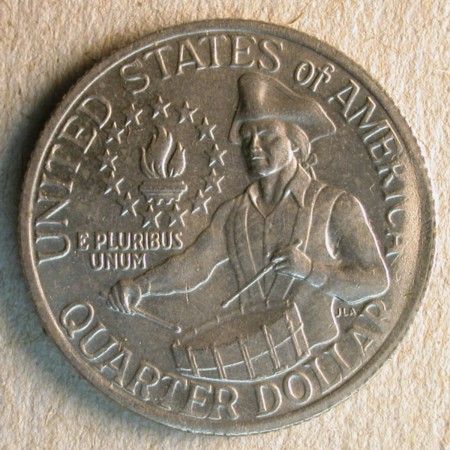

This 1976 quarter dollar was struck on a planchet derived from a section of bonded strip that never had one of its clad layers. It weighs 5.39 grams — 0.28 grams underweight. A normal missing-before-strike clad error should weigh a full gram less than a normal quarter. The reason it’s not full weight (5.67g) is that the right side shows a taper. This is consistent with this blank being derived from an area near the leading or trailing end of the clad strip.