PART VI. Striking Errors:

Collar Deployment Errors:

Partial collar

Definition: A coin struck within a partially deployed collar.

A partial collar error is one in which the planchet is only partially confined by the collar. The lower half of the edge shows contact with the working face of the collar while the upper half of the edge is smooth, beveled, or both.

A collar can occupy a partially deployed condition for two reasons:

1. It might have been depressed part of the way toward the anvil die face by the pressure applied by a tight-fitting or poorly centered planchet (backed, of course by the hammer die).

2. It might never have occupied a fully elevated position. Its deployment may have been blocked by a poorly centered coin (in presses where the anvil die is fixed and the collar moves up and down). Its deployment might have been interrupted for other reasons, such as debris getting trapped between the collar and the anvil die neck.

A partial collar error can be level or it can be tilted. Tilt can be so great in some instances as to leave one pole fully in contact with the collar and the other completely above the collar. The transition between the collar-struck portion of the edge and the unstruck portion can be abrupt or can be separated by a beveled interval. This zone is caused by contact with the beveled entrance of the collar. The beveled entrance can be wide, narrow, or sometimes absent. The beveled entrance often shows horizontal machining marks, which are transferred to the edge of the coin. In presses with a standard or traditional setup, the collar-struck edge is next to the reverse face (struck by the anvil die). In the inverted setup, the collar-struck edge lies next to the obverse face (struck by the anvil die). The latter setup is also called a “reverse partial collar” or a “reversed partial collar”. Uneven machining along the top of the collar’s working face can generate an undulating partial collar. When a coin returns to the collar for another strike, it often has trouble fitting back into it. It may depress the collar partway, resulting in a “re-entry partial collar”.

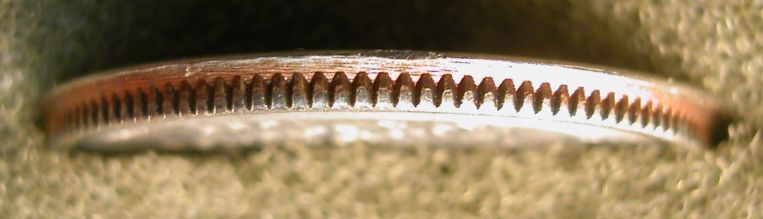

The edge of this 2000 New Jersey quarter dollar shows a level partial collar error with a bevel above the reeding. The bevel was caused by contact with the beveled entrance of the collar. Typical horizontal machining marks appear on the beveled surface of the coin’s edge.

This 1978 quarter dollar was struck within a severely tilted collar. The left side is fully reeded while the right side is smooth. In order to show the entire edge, the photo was taken with the coin sitting in a flashlight reflector.

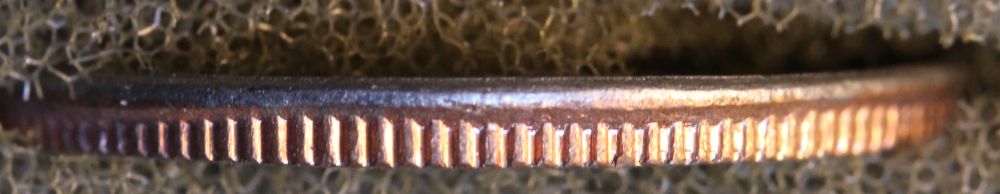

This 1996-D dime shows a reversed partial collar. It was struck in a press with an inverted die setup (reverse die as hammer die).

This 1994-P dime shows an undulating partial collar. The beveled entrance was machined unevenly, so that the upper margin of the collar’s working face follows a wavy path.