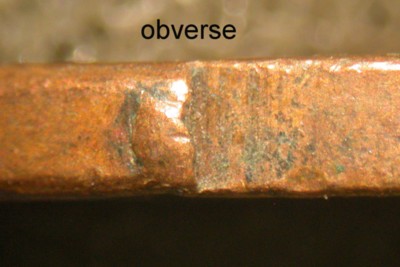

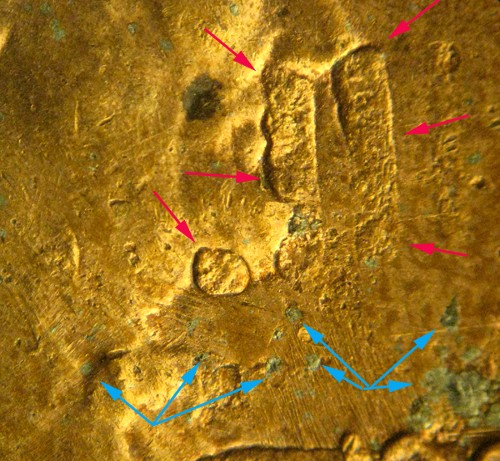

PART VI. Striking Errors:

Retained Struck-through

Metal Foil:

Definition: Both metal foil and a planchet entered the striking chamber and were struck together. The metal foil adhered to the struck coin.

This 2006 Silver Eagle had a piece of metal foil enter the striking chamber at the same time as the planchet. Whether the foil was adhered to the planchet before the strike is unknown. However, the piece of foil remained in place after the strike to form a retained struck-through.