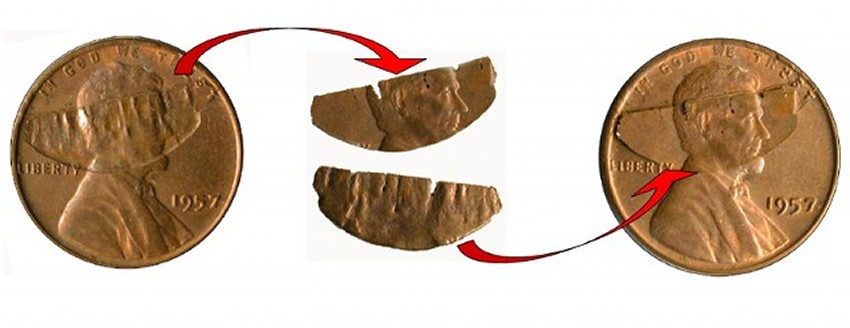

PART III. Die installation Errors:

Mules:

Wrong anvil die

Definition: Mules are coins struck by mismatched dies. In this case the wrong anvil die was installed in a coin press.

This Malaysian 10 sen mule was struck on a 10 sen planchet in a reeded 10 sen collar and carries a normal 10 sen obverse. The reverse face was struck by a 1 sen reverse (anvil) die.

This dual denomination mule was struck in 1993 by the Denver mint. It had the correct hammer die (cent die) and the coin was struck on the correct planchet. However, the anvil die (dime die) was mistakenly installed in the coin press which resulted in this unique combination.

This dual denomination mule coin was struck in 1999 by the Philadelphia mint. It had the correct hammer die (cent die) and the coin was struck on the correct planchet. However, the anvil die (dime die) was mistakenly installed in the coin press which resulted in this unique combination.

Images courtesy of Heritage Auctions