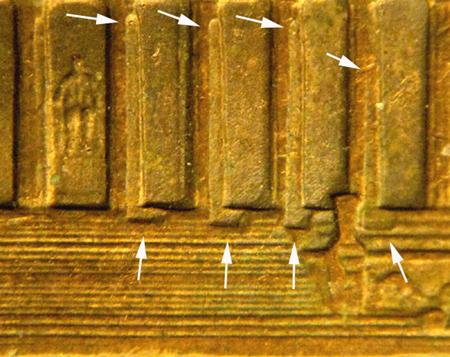

PART V. Planchet Errors:

Lamination:

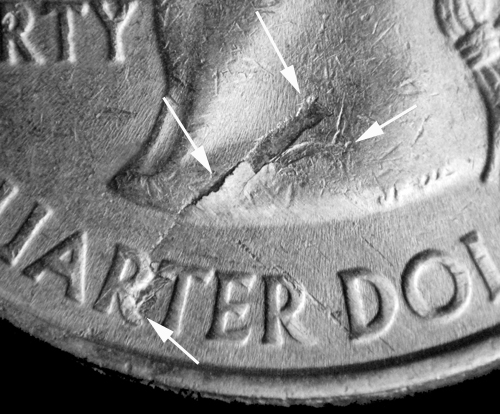

Lamination loss after strike:

Definition: Flakes of metal can peel off the surface of a coin after the strike. Such defects are generally attributed to the presence of contaminants in the alloy. In some instances, flakes of metal lift off the face of a coin as the result of an inadequately mixed alloy.

The 1958-D Washington quarter pictured above shows two areas where flakes spalled off the coin after the strike (indicated by black arrows).