Part V: Planchet Errors:

Blanking and Cutting Errors:

Incomplete punch (a.k.a, incomplete clip):

Definition: An incomplete punch represents an area of the coin metal strip where the blanking die (punch) failed to penetrate completely. If the strip fails to advance properly, the blanking die will slice through part of the circular punch mark, creating a blank with a crescentic punch mark.

Incomplete punch errors may be derived from portions of the strip used to adjust the depth of penetration of the blanking die. However, their frequent co-occurrence with conventional curved clips suggests that they can develop spontaneously and at any point along the strip.

Genuine incomplete punch errors are quite rare. The following diagnostics will assist in identifying an authentic incomplete punch:

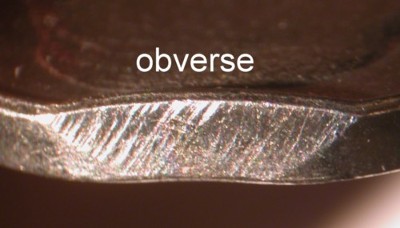

1. A genuine incomplete punch is very sharp and narrow.

2. A genuine incomplete punch penetrates the surface of the coin.

3. On both faces, the surface of the coin should be undistorted on either side of the punch mark.

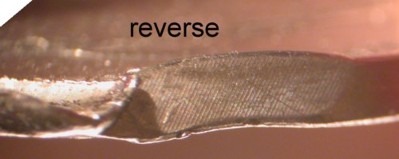

4. A genuine incomplete punch will be visible on the edge of the coin.

For expanded treatment concerning clipped coin diagnostics click here.

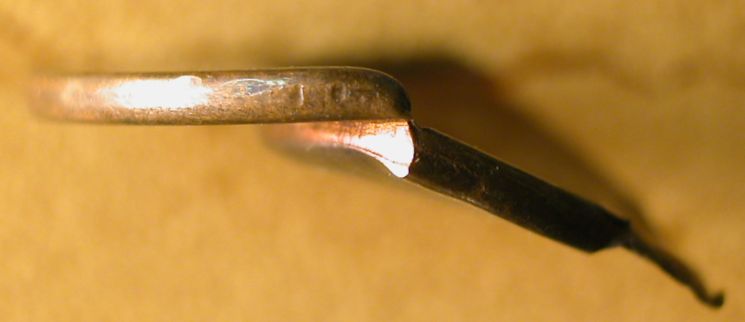

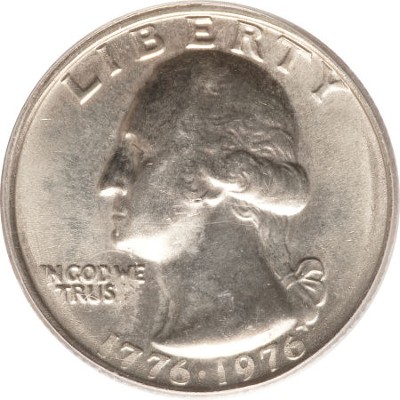

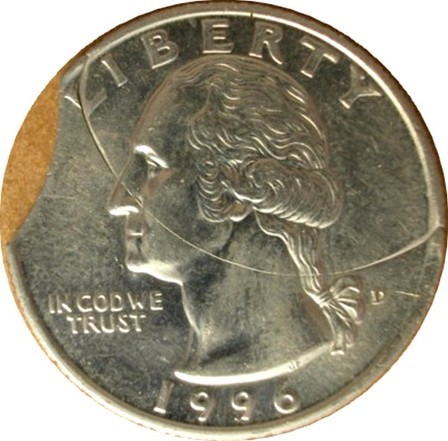

The 1996-D quarter shown here has both an incomplete punch and a conventional curved clip.

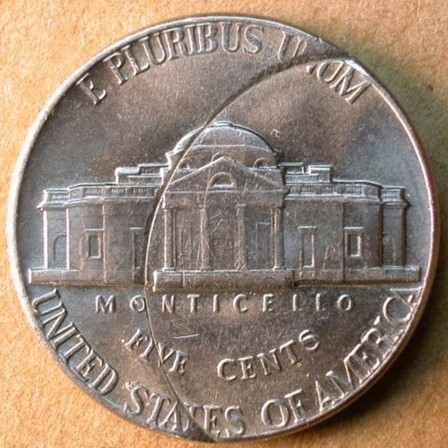

Below is a 1974 Jefferson nickel with a genuine incomplete punch error.

Below are images of the only known example of an off-center strike on a planchet with an incomplete punch. In its first attempt, the blanking die fell just short of punching out a blank. In it’s second attempt, the blanking die sliced through the incompletely punched hole in the coin metal strip. Later on the coin received a tiny off-center uniface strike. The only die-struck elements are the last two letters of GOD.

This image depicts what was originally the upper surface of the coin metal strip. You can see how the blanking die pushed in a circular area of metal, generating a step-down in the middle of the planchet.

This image shows what was originally the bottom surface of the coin metal strip. This surface was eventually struck by the obverse (hammer) die. Orientation of any planchet relative to the dies is a random affair.

The pushing/shearing action generated by the blanking die and the opposing hole in the perforated base plate produced a dramatic step in the middle of the planchet.