Part V. Planchet Errors:

Blanking and Cutting Errors:

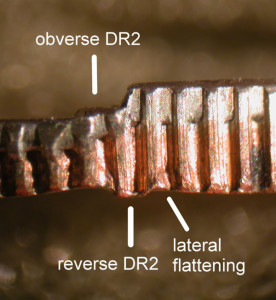

Cutting Burr

Definition: A burr that is generated when the ends or sides of the strip are trimmed or when the strip is split longitudinally. When a shearing blade, saw, or guillotine trims the strip, this may generate a burr along the trimmed edge. If this burr curls over onto the surface of the strip and this area is subsequently sliced through by a blanking punch, the result is a straight clip blank with a burr that will eventually be struck into the coin. The coin will show a straight clip that is paralleled by a narrow fissure. The fissure marks the internal edge of the struck-in cutting burr. Almost all cutting burrs are restricted to one face.

The fissure that marks the edge of a struck-in cutting burr used to be erroneously identified as an “incomplete straight clip”. It was also once thought that the fissure was a scar produced by a guide or stop next to the cutting edge.

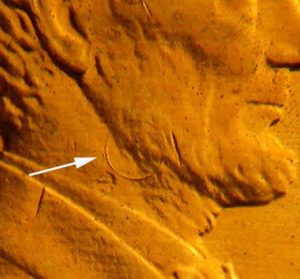

Struck sometime between 1980 and 1982, this copper-alloy Lincoln cent shows a straight clip and, next to it, a struck-in cutting burr. The fissure demarcating the internal edge of the burr is easily seen.

Images courtesy of Jon Sullivan

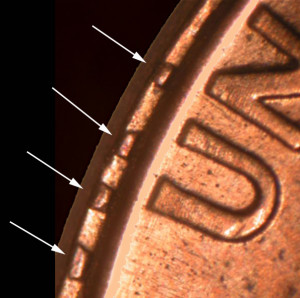

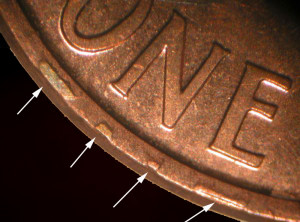

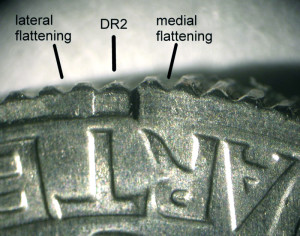

This 2008-P Oklahoma quarter is the only known example of a straight clip with cutting burrs on both faces. Metal derived from the copper core curled onto both faces and was eventually struck into both faces. Fissures marking the internal edge of the cutting burrs are easily seen.