PART VI. Striking Errors:

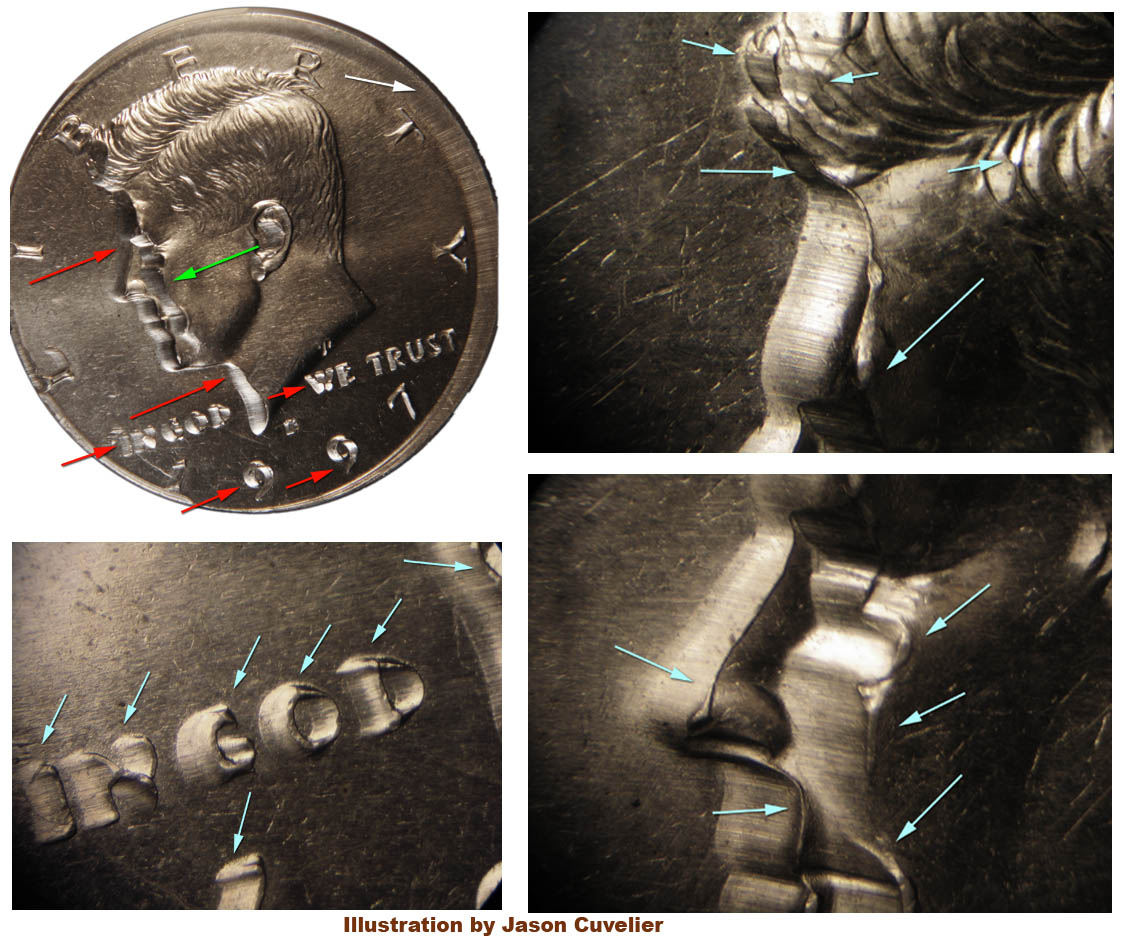

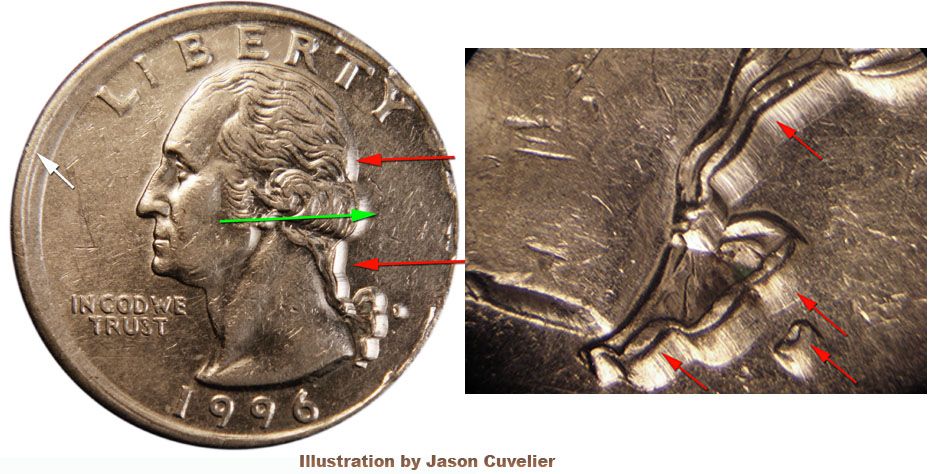

Machine Doubling:

Slide Doubling

Definition: In this form of doubling, a die drags itself through the newly-struck design, smearing the features. Strong cases of slide doubling are always restricted to the face struck by the hammer die. After reaching the lowest point of its downstroke, the hammer die shifts to one side without bouncing. As it drags itself across the newly-struck design, it piles coin metal into a series of ridges. Weak cases of slide doubling found on the reverse face have previously been assigned to “ejection doubling”, but there is no way to prove that this is actually what happened.

Forms of machine doubling combining elements of both push doubling and slide doubling do occur.

A very severe case of slide doubling is seen on this 2001-D cent. As is often the case, it is accompanied by a design ablation error. The hammer die first contacted the coin in a centered position. As it sank down into the planchet, the hammer die shifted to the northeast, erasing the newly-struck design in a crescentic area in the southwest. Having completed its downstroke in a misaligned position, the hammer die then shifted back toward the southwest, dragging itself through the newly-struck design. The design is grotesquely smeared as a result.

On the two examples (Kennedy half and Washington quarter) the green arrow indicates the direction the die traveled as contact was made (Die Ablation), with the white arrow showing the scraped planchet face. The red arrows show both the direction the die took as it returned and also shows the areas where the metal was moved and piled up. The light green arrows show details of the Slide Doubling on the Kennedy half.